Sustainable magnetic NdFeB-powders for highest requirements

Our product portfolio

Discover our recycled magnetic powders made from neodymium iron boron (NdFeB). Our advanced recycling process offers an environmentally friendly solution that conserves resources and increases efficiency in various applications. Our powders are customised for use in high-performance plastic-bonded neodymium-iron-boron magnets. This is a versatile and powerful class of magnets produced by combining permanent magnetic powders with plastic binders. This combination enables the production of complex shapes and diverse designs, making them ideal for applications that require specific shapes and customisation capabilities.

The magnetic properties of our recycled powders

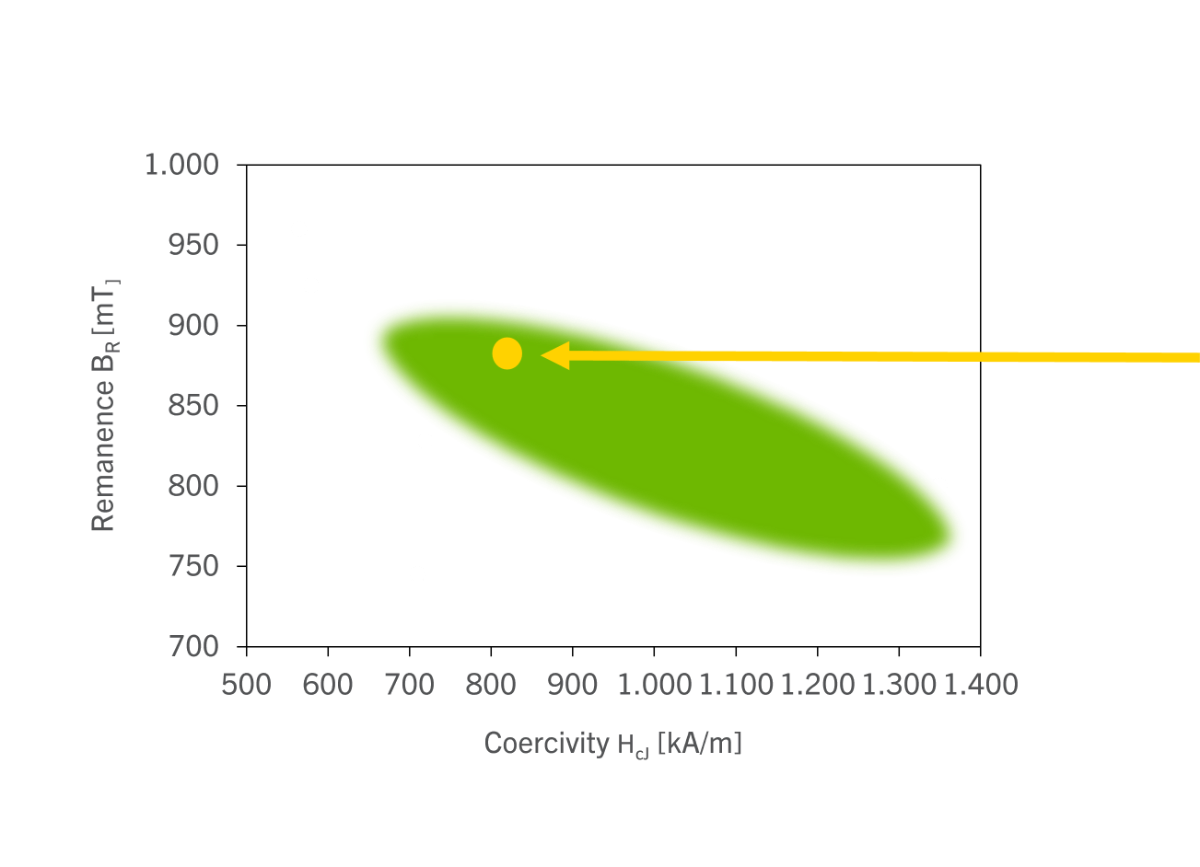

Thanks to our innovative recycling process, we have many options for customising the magnetic properties of the recycled powders. The majority of technologically relevant powder properties can already be covered by recycling. The "map" of important magnetic parameters such as remanence (Br) or coercivity (Hcj) gives an impression of which magnetic powders can be produced using our recycling process. If certain magnetic parameters are not currently shown there, we would be pleased to hear from you so that we can work together to find a customised solution for you.

Remloy offers a wide range of specifications according to customer needs

Remloy can offer specifications that are commonly used by the industry to ensure easy substitution of current magnetic material with recycled material.

Example for commonly used specification:

HRM-B-870/45-820/75

► Br[mT]: 820 - 935

► HcJ[kA/m]: 735 - 905

► BHmax [kJ/m2]: 102 - 122

"Without NdFeB magnets, electric motors can be up to three times larger and heavier in order to achieve the same performance with higher energy consumption"

The advantages of neodymium-iron-boron magnets in electric motors

- Power: Neodymium-iron-boron magnets offer an exceptionally high energy density, enabling electric motors to achieve high performance in a small volume.

- Size and weight: Due to their high magnetic strength, NdFeB magnets enable a more compact and lighter design of motors, ideal for space-critical applications.

- Durability and reliability: Heraeus Remloy provides long-lasting magnets that ensure consistently high performance, reducing maintenance frequency and costs.

- Efficiency: Neodymium magnets contribute to the efficiency of motors as they have fewer energy losses due to heat generation. This leads to better energy utilisation.

- Precision and control: Strong magnetic fields enable precise control of motor performance and increase control over motor functions, essential for advanced control technologies.

Fields of application

Our recycled powders get the best out of plastic-bonded magnets. They have excellent corrosion resistance, are mechanically stable and have a high energy product.

These properties make them particularly attractive for applications in areas such as electronics, the automotive industry, e-bikes or household appliances, where precision and versatility are required. Their ability to be produced in complex shapes and with high precision opens up a wide range of applications, from motors, sensors and actuators to consumer electronics.